Rotary Adsorption MachinE

We have used our considerable experience in large slow speed rotating machines to adapt our rotary APH technology into a rotary sorbent adsorber for todays most advanced carbon capture system.

POINT SOURCE CO2 CAPTURE

There is growing interest in adsorption based post-combustion CO2 capture technology for industrial flue gas point source applications, due to its combined potential of reducing energy penalty and ease of retrofitting to existing plants with less total footprint. With low-temperature sorbent based adsorption systems, a suitable ‘contactor’ or ‘reactor’ for the sorbent bed is a key factor for the efficiency utilization of the sorbent.

There are multiple possible configurations of fixed, moving, rotating, and fluidized sorbent beds, and the reactor configuration decision is based on many factors, one of which is the regeneration mode that is generally dictated by the sorbent and CO2 partial pressure of the flue gas.

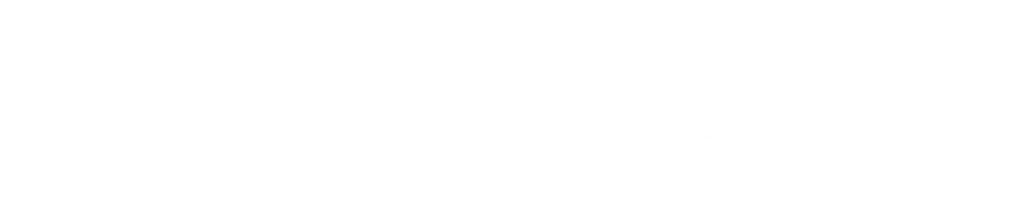

With our expertise of large rotating equipment, LJUNGSTRӦM has developed a new scalable rotating absorption machine design for use with a low temperature swing adsorption process developed by SVANTE Inc.

COMMERCIAL SCALE ROTARY ABSORPTION MACHINES

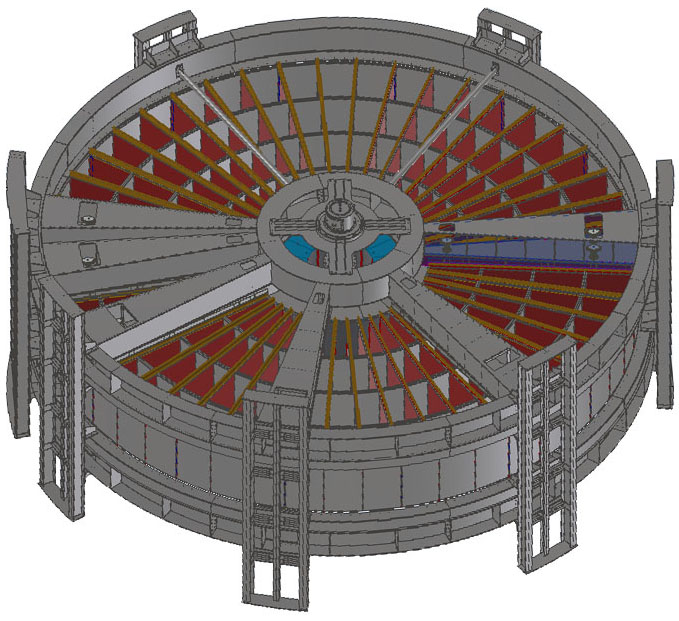

LJUNGSTRӦM have used our wide experience of designing both high temperature air preheaters and low temperature gas-gas heaters, and incorporated best practices for equipment design for a highly reliable slow speed machine design that can cope with the temperature and pressure variations.

SPECIAL VERTICAL ARRANGEMENT

A special vertical shaft rotor arrangement allows for different sorbent media heights, with unique design considerations to provide a highly accurate machine with predictable surface elevations for a high efficiency sealing system. All rotating loads are transmitted to a low-cost free standing support structure that provides easy access for maintenance to bearings and seal assemblies.