The 340MW Collie Power Station located in Western Australia started operation in 1999 with air preheaters supplied by Nitchitsu, Japan. The Rothemuhle air preheaters are a complex twin-flow design and one of the toughest to maintain due to the complexity of the design and rotating hood sealing arrangements. With significant operational problems plaguing the plant between overhaul periods, the customer was looking for a single service provider to solve all their problems.

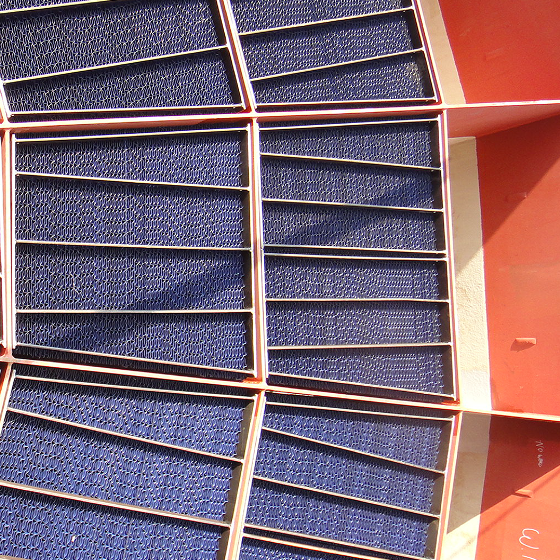

After analyzing the equipment design and performance, LJUNGSTRÖM developed a turnkey package of technical solutions and upgrades that improved the equipment performance beyond the original OEM specifications. The latest technology in heat transfer elements were supplied in custom designed basket containers, to replace older legacy technology, along with a complete replacement of many of the sealing system components to effectively overhaul the air preheater to as-new condition.

LJUNGSTRÖM executed the project as a turnkey contractor to the customer who closely monitored all aspects of the project work, with close attention made to all Health, Safety and Environmental requirements. Upwards of 18,000 manhours were employed in the implementation of the entire solution, which was a significant achievement for the team in Australia during restrictions imposed by the COVID pandemic.

With completion of the project, significant performance benefits have been confirmed by the end user, and all guarantees were achieved, including a dramatic drop in losses due to leakage and fan power leading to considerable savings for the operators. “This is a key project for LJUNGSTRÖM to illustrate our capabilities and success of our solutions that can be applied to both Rothemuhle as well as LJUNGSTRÖM air preheaters. There is great interest in solutions that reduce operators maintenance cost, while stretching periods between replacement parts, and we are focused on helping customer achieve their operational goals” said Thomas Barwald, Managing Director, LJUNGSTRÖM Australia.

LJUNGSTRÖM continue to challenge the outdated practice of maintaining equipment without implementing the latest technology for improved performance and operation, and the successful turnkey execution of this project and the performance results achieved demonstrate the capabilities of LJUNGSTRÖM to offer products and services for non-OEM equipment.