INSIGHTS

Latest Insights and

Developments at LJUNGSTRÖM

Stay informed with the latest news, project updates, industry trends,

and company milestones shaping our journey toward

a more sustainable future.

Ljungström news and updates

Innovations, projects, and industry highlights

LJUNGSTRÖM & HaF Equipment Join Forces to Expand Global Acid Gas Mitigation Solutions

LJUNGSTRÖM & HaF Equipment Join Forces to Expand Global Acid Gas Mitigation Solutions We’re excited to announce our worldwide collaboration including an international licensing agreement to sell HaF’s cutting-edge HaF lime injection technology overseas. This...

Tailored Solutions for Carbon Capture Feed Gas Pretreatment

We are excited to share a major milestone that underscores LJUNGSTRÖM’s leadership in delivering advanced solutions to our customers. This week, our teams from LJUNGSTRÖM and Econotherm (UK) Ltd are meeting in Germany to drive forward our shared mission of advancing...

LJUNGSTRÖM Acquires Leading Technology for Acid Gas Mitigation

LJUNGSTRӦM has acquired outright the SBS/HBS flue gas acid mitigation technology developed over many years by AECOM, who will continue to serve their existing customer installations in the USA under a maintenance license with LJUNGSTRÖM. This acquisition facilitates...

LJUNGSTRÖM Supports Offshore Wind on America’s East Coast

LJUNGSTRӦM has signed a contract with Riggs Distler & Company, Inc. to provide specialized structural steelwork for another offshore wind project. Ocean Wind I, New Jersey’s first offshore wind project developed by U.S. offshore wind leader Ørsted, will be located 15...

LJUNGSTRÖM Receives Air Preheater Order for Vietnam

LJUNGSTRӦM has secured an order to supply tri-sector air preheaters for a high efficiency ultra-supercritical 1200MW coal-fired power plant in Vietnam. The power plant project, located in the North Central Coast of Vietnam, is expected to be commissioned in 2024, and...

LJUNGSTRÖM Selected as Key Supplier for New York’s Latest Wind Project

LJUNGSTRӦM has signed a contract with Riggs Distler & Company, Inc. to provide specialized structural steelwork for New York’s latest offshore wind project, Sunrise Wind. The wind farm joint development partnership between Ørsted and Eversource has the capacity to...

LJUNGSTRÖM – Doing Our Part to Help Lower NOx Emissions

LJUNGSTRÖM continues to support the implementation of ultra-low emissions in the Chinese iron and steel industry with its gas-gas heaters (GGH) for flue gas Selective Catalytic Reduction (SCR) De Nitrification plants. These SCR plants are typically a retrofit to the...

LJUNGSTRÖM Completes Rapid Gas-Gas Heater Replacement in Eastern Japan

A sintering plant at a major steel works in Eastern Japan had a horizontal design Ljungström gas-gas heater (GGH) that had been operating for more than 40 years. The GGH had a rotor diameter of more than 10 meters, and during the past 3-4 years had been facing...

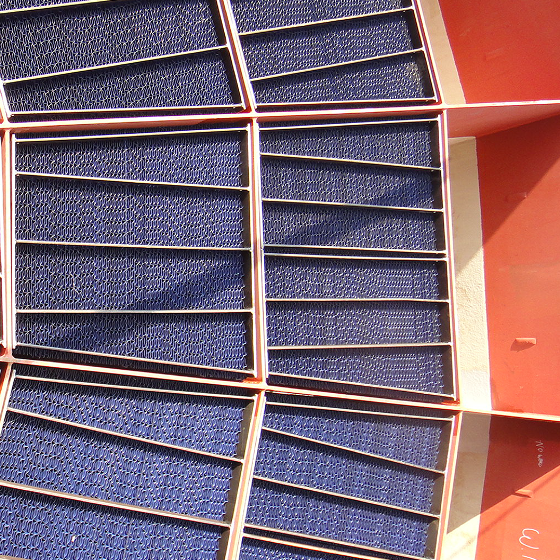

Expanding Capabilities to Provide Turnkey Service on Competitors Equipment

LJUNGSTRÖM has successfully completed a major overhaul of 20 year old Rothemuhle-type air preheaters in Western Australia. The 340MW Collie Power Station located in Western Australia started operation in 1999 with air preheaters supplied by Nitchitsu, Japan. The...

LJUNGSTRÖM & HaF Equipment Join Forces to Expand Global Acid Gas Mitigation Solutions

LJUNGSTRÖM & HaF Equipment Join Forces to Expand Global Acid Gas Mitigation Solutions We’re excited to announce our worldwide collaboration including an international licensing agreement to sell HaF’s cutting-edge HaF lime injection technology overseas. This...

Tailored Solutions for Carbon Capture Feed Gas Pretreatment

We are excited to share a major milestone that underscores LJUNGSTRÖM’s leadership in delivering advanced solutions to our customers. This week, our teams from LJUNGSTRÖM and Econotherm (UK) Ltd are meeting in Germany to drive forward our shared mission of advancing...

LJUNGSTRÖM Acquires Leading Technology for Acid Gas Mitigation

LJUNGSTRӦM has acquired outright the SBS/HBS flue gas acid mitigation technology developed over many years by AECOM, who will continue to serve their existing customer installations in the USA under a maintenance license with LJUNGSTRÖM. This acquisition facilitates...

LJUNGSTRÖM Supports Offshore Wind on America’s East Coast

LJUNGSTRӦM has signed a contract with Riggs Distler & Company, Inc. to provide specialized structural steelwork for another offshore wind project. Ocean Wind I, New Jersey’s first offshore wind project developed by U.S. offshore wind leader Ørsted, will be located 15...

LJUNGSTRÖM Receives Air Preheater Order for Vietnam

LJUNGSTRӦM has secured an order to supply tri-sector air preheaters for a high efficiency ultra-supercritical 1200MW coal-fired power plant in Vietnam. The power plant project, located in the North Central Coast of Vietnam, is expected to be commissioned in 2024, and...

LJUNGSTRÖM Selected as Key Supplier for New York’s Latest Wind Project

LJUNGSTRӦM has signed a contract with Riggs Distler & Company, Inc. to provide specialized structural steelwork for New York’s latest offshore wind project, Sunrise Wind. The wind farm joint development partnership between Ørsted and Eversource has the capacity to...

LJUNGSTRÖM – Doing Our Part to Help Lower NOx Emissions

LJUNGSTRÖM continues to support the implementation of ultra-low emissions in the Chinese iron and steel industry with its gas-gas heaters (GGH) for flue gas Selective Catalytic Reduction (SCR) De Nitrification plants. These SCR plants are typically a retrofit to the...

LJUNGSTRÖM Completes Rapid Gas-Gas Heater Replacement in Eastern Japan

A sintering plant at a major steel works in Eastern Japan had a horizontal design Ljungström gas-gas heater (GGH) that had been operating for more than 40 years. The GGH had a rotor diameter of more than 10 meters, and during the past 3-4 years had been facing...

Expanding Capabilities to Provide Turnkey Service on Competitors Equipment

LJUNGSTRÖM has successfully completed a major overhaul of 20 year old Rothemuhle-type air preheaters in Western Australia. The 340MW Collie Power Station located in Western Australia started operation in 1999 with air preheaters supplied by Nitchitsu, Japan. The...

LJUNGSTRÖM & HaF Equipment Join Forces to Expand Global Acid Gas Mitigation Solutions

LJUNGSTRÖM & HaF Equipment Join Forces to Expand Global Acid Gas Mitigation Solutions We’re excited to announce our worldwide...

Tailored Solutions for Carbon Capture Feed Gas Pretreatment

We are excited to share a major milestone that underscores LJUNGSTRÖM’s leadership in delivering advanced solutions to our customers. This...

LJUNGSTRÖM Acquires Leading Technology for Acid Gas Mitigation

LJUNGSTRӦM has acquired outright the SBS/HBS flue gas acid mitigation technology developed over many years by AECOM, who will continue to...

LJUNGSTRÖM Supports Offshore Wind on America’s East Coast

LJUNGSTRӦM has signed a contract with Riggs Distler & Company, Inc. to provide specialized structural steelwork for another offshore wind...

LJUNGSTRÖM Receives Air Preheater Order for Vietnam

LJUNGSTRӦM has secured an order to supply tri-sector air preheaters for a high efficiency ultra-supercritical 1200MW coal-fired power...

LJUNGSTRÖM Selected as Key Supplier for New York’s Latest Wind Project

LJUNGSTRӦM has signed a contract with Riggs Distler & Company, Inc. to provide specialized structural steelwork for New York’s latest...

LJUNGSTRÖM – Doing Our Part to Help Lower NOx Emissions

LJUNGSTRÖM continues to support the implementation of ultra-low emissions in the Chinese iron and steel industry with its gas-gas heaters...

LJUNGSTRÖM Completes Rapid Gas-Gas Heater Replacement in Eastern Japan

A sintering plant at a major steel works in Eastern Japan had a horizontal design Ljungström gas-gas heater (GGH) that had been operating...

Expanding Capabilities to Provide Turnkey Service on Competitors Equipment

LJUNGSTRÖM has successfully completed a major overhaul of 20 year old Rothemuhle-type air preheaters in Western Australia. The 340MW...

Ready to discuss solutions that work for your needs?

No matter the challenge, our experts are here to help you achieve unmatched efficiency and reliability. Let’s discuss your needs today.