THERMAL

Field Assembled

Ljungström®

Air Preheaters

Our high-efficiency, modular air preheaters set the global standard for large-scale flue gas heat recovery. Designed for durability, seamless integration, and peak performance, they optimize efficiency while reducing operational costs.

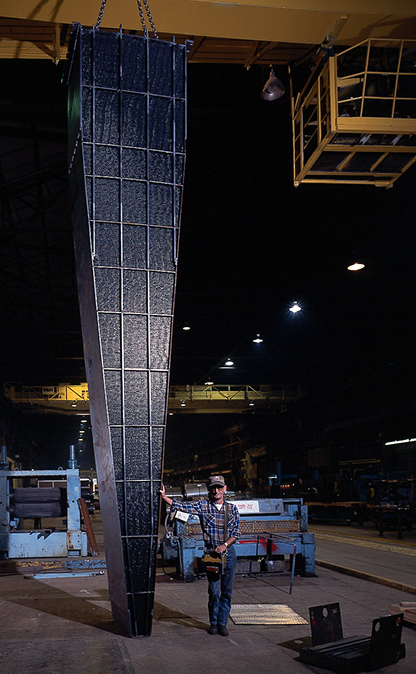

Large sized Ljungström rotary air preheaters

Custom-built onsite for maximum thermal efficiency

Key Advantages of

Ljungström® Air Preheaters

Enhanced efficiency, reduced leakage and corrosion,

long-term savings. Versatile modular designs for diverse

needs. The global standard in regenerative heat exchange.

Optimized Efficiency and Performance

Advanced heat transfer surfaces maximize thermal efficiency and minimize pressure drop.

Engineered sealing solutions reduce air-to-gas leakage, improving overall performance.

Durable and

Low Maintenance

Built with robust drive systems and premium materials for long-term reliability.

Optimized sealing solutions and low-maintenance auxiliary systems reduce upkeep.

Customizable and Scalable

Available in bi-sector, tri-sector, and quad-sector configurations for various boiler types.

Flexible support arrangements (center or peripheral) to meet industrial and utility needs.

Cost-effective

and Sustainable

Maximized heat recovery lowers fuel consumption, operational costs, and carbon footprint.

Optimized erection sequence and durable construction minimize installation and maintenance expenses.

Air Preheaters for

Every Application

Maximum Flexibility

Adaptable to power plants fueled by coal, oil, gas, or biomass, our modular designs offer first-class technology tailored for any application.

Engineered

for Every Need

Scalable for Any Size

As power plants continue to expand, our air preheaters evolve to match their scale. With configurations available in a wide range of sizes, including those designed for the world’s largest power plants, we ensure optimal heat recovery and performance at any capacity.

A Century of

Engineering Excellence

The Original Innovators

LJUNGSTRÖM has been the global standard in regenerative air preheaters since the 1920s. With a legacy of innovation and ownership of all Ljungström® patents, our solutions are trusted more than any other heat exchanger worldwide.

Unrivaled Expertise

No one understands Ljungström® Air Preheaters better than we do. Our engineering excellence is backed by a legacy of industry-leading names, including SRM, Air Preheater Company, Kraftanlagen, Gadelius, Stein, PBS, and APEL. Recognized by boiler manufacturers, utilities, and industrial leaders worldwide, our air preheaters are trusted more than any other heat exchanger.

Ready to discuss solutions that work for your needs?

No matter the challenge, our experts are here to help you achieve unmatched efficiency and reliability. Let’s discuss your needs today.