ENERGY TECHNOLOGY | POWER + INDUSTRIAL

Acid Gas Removal

Proven injection technologies to provide

fuel-specific SO3 mitigation solutions

with low consumption and flexible plant

configurations to generate benefits

beyond opacity control.

Advanced acid gas control

Protecting equipment and environment from harmful emissions

TECHNOLOGY SOLUTIONS

Solving SO3 Challenges

Cleaner, Smarter Operations

SO3 may be a minor pollutant, but its impact on combustion boilers, power, and industrial systems is significant – affecting SCR, APH, ESP, GGH, and stack performance. Removing SO3 not only enhances system efficiency but also delivers substantial economic benefits with a fast payback and strong ROI.

Prevented Sulfuric Acid Corrosion

Eliminated APH Ammonium Bisulfate Scaling

Improved Boiler Efficiency, Reducing Fuel Consumption

Our SBS Injection™ and LBS Injection™ technologies seamlessly integrate into plant operations, maximizing benefits when applied ahead of the SCR and APH, but also effective before particulate collectors or wet scrubbers.

SBS Injection™

Sodium Based Acid Gas Control

Up to 99.9% SO3 removal before it impacts equipment, preventing corrosion, APH plugging, and visible plumes.

- Prevents sulfuric acid corrosion

- Reduces APH scaling and fouling

- Enhances efficiency and compliance

LBS Injection™

Lime Based Acid Gas Control

A cost-effective, dry lime injection system removing up to 99% of SO3, reducing fouling, and extending equipment life.

- Prevents sulfuric acid corrosion

- Reduces APH scaling and fouling

- Enhances efficiency and compliance

TECHNOLOGY SOLUTIONS

Proprietary

Injection Technology

Optimized SO3 Removal

with Precision Engineering

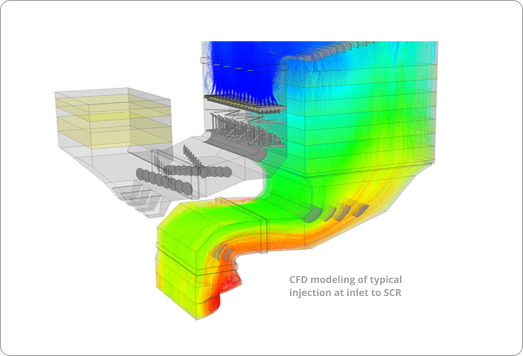

Our SBS Injection™ technology features a proprietary lance design utilizing ultra-fine atomization and optimized using computational fluid dynamics (CFD) modeling. This ensures uniform reagent distribution, maximum SO3 removal efficiency, and minimal reagent usage – preventing downstream deposition and optimizing plant performance. Simple means better.

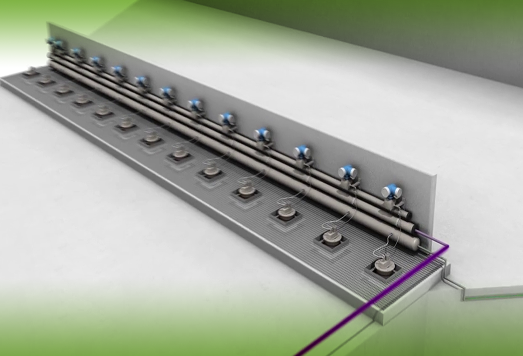

Proprietary Injection Lance System

CFD modelling of typical injection at inlet to SCR

PROVEN EXPERTISE

Experience That Counts

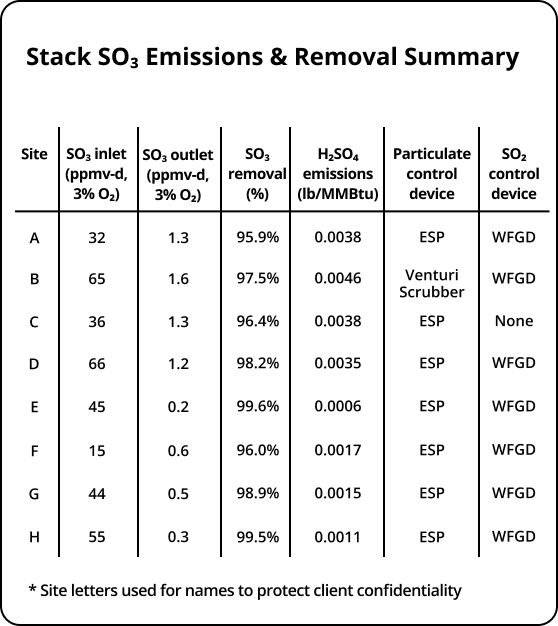

The LJUNGSTRÖM SBS and LBS Injection process has been successfully applied to over 40 boilers, covering over 25,000 MW

Up to 99.9% SO3 Removal at low reagent usage

Proven performance upstream of air heaters and SCRs

Reduces sulfuric acid corrosion and opacity issues while improving efficiency

Backed by two decades of operation, our solution ensures compliance with current and future BACT (Best Available Control Technology) standards.

Ready to discuss solutions that work for your needs?

No matter the challenge, our experts are here to help you achieve unmatched efficiency and reliability. Let’s discuss your needs today.