ADVX FLX FOR

OPERATIONAL FLEXIBILITY

Make the most of your air preheater

LJUNGSTRÖM’s innovative AdvX® FLX is built to remove operational restraints allowing more flexible operation providing significant business savings in both the short and long term.

Optimize Your Plant

Improve Operations

Expanded capabilities with improved plant operations ensure significant long-term savings.

Eliminate Operating Constraints

Enjoy flexible operation, and do

more with your existing systems.

UPGRADE YOUR PLANT WITH ADVX® FLX

A low cost upgrade to existing systems, LJUNGSTRÖM’s AdvX® FLX will maximize your plant operational flexibility and minimize your O&M costs, and all by utilizing your current equipment in a more efficient way.

Enhanced Air Preheater (APH) Operations

AdvX® FLX will substantially reduce fouling, corrosion, and maintenance costs by increasing APH average cold end temperatures (ACET).

Temperature Control

AdvX® FLX can increase flue gas temperature to your Spray Dry Absorber (SDA) or Circulating Dry Scrubber (CDS), and increase mill temperature.

ADVX® FLX Can Give You Operational Flexibility

As plants are expected to run at lower loads and capacity factors more often, many systems were not designed with low capacity factors in mind. This can present operational challenges and constraints due to cycling generation profiles.

Operational constraints can include:

- SDA/CDS

– SO2 removal

– Wastewater (process water) evaporation capacity

– Minimum load / temperature

- Unit

– Coal moisture / mill temp

– APH average cold-end temperatures (ACET)

– Acid dewpoint

Typical Benefits and Scope

LJUNGSTRÖM’s AdvX® FLX is a low-cost system which can mitigate or eliminate these issues with little to no net heat rate impact when coupled with an APH upgrade – affording power plants increased operational flexibility.

System benefits include:

- Increasing dry scrubber inlet temperature

- Increasing mill temperature

- Increasing APH ACET

The typical scope of the system is:

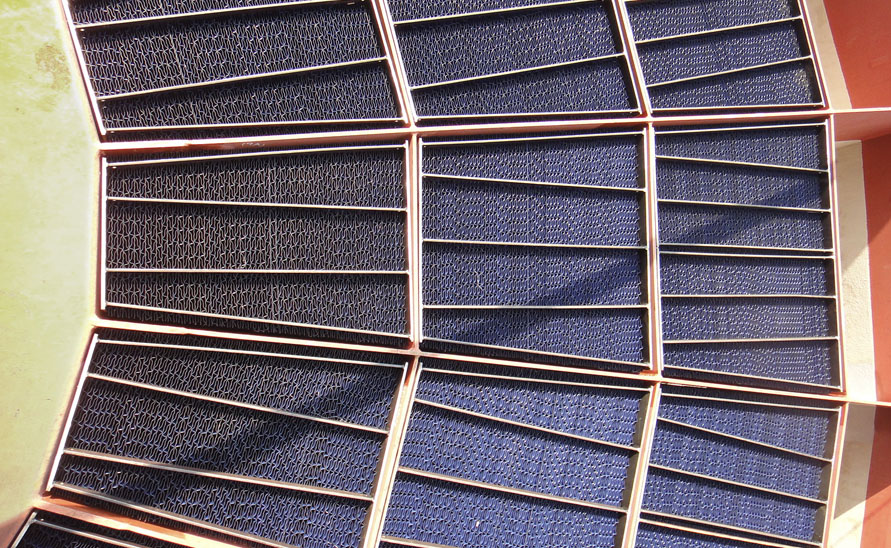

- High efficiency APH element configuration

- X-ratio management with air or gas bypass

- Load specific heat recovery optimization

CASE STUDY

A utility was forced into operating and maintaining a costly, temporary wastewater treatment system due to low capacity factors resulting in reduced evaporation capacity in their SDA.

LJUNGSTRÖM’s AdvX® FLX solution incorporated an upgrade to the air preheater that will improve wastewater evaporation and eliminate the costs of additional waste water treatment.

At low loads, the system will;

– Increase SDA inlet temperature by 20°F

– Increase ACET by 10°F

– Increase mill temp by 10°F

– With an improvement to heat rate at high loads